Any casual tourist in a region of past Roman occupation will likely come across the concrete ruins of an empire that still persist after thousands of years of human activity and weather. For centuries, many thought the secrets of what made these Roman structures so durable were lost. Buildings like the Pantheon in Rome are emblematic of this inquiry, still standing very nearly just as it was when it was constructed around 117 CE. The Pantheon remains to this day the world’s largest unreinforced concrete dome; a feat that no modern construction company could hope to replicate. It has not only survived the tides of humanity ebbing and flowing around it but has also withstood countless earthquakes which have leveled the buildings and other structures surrounding it even in more modern times.

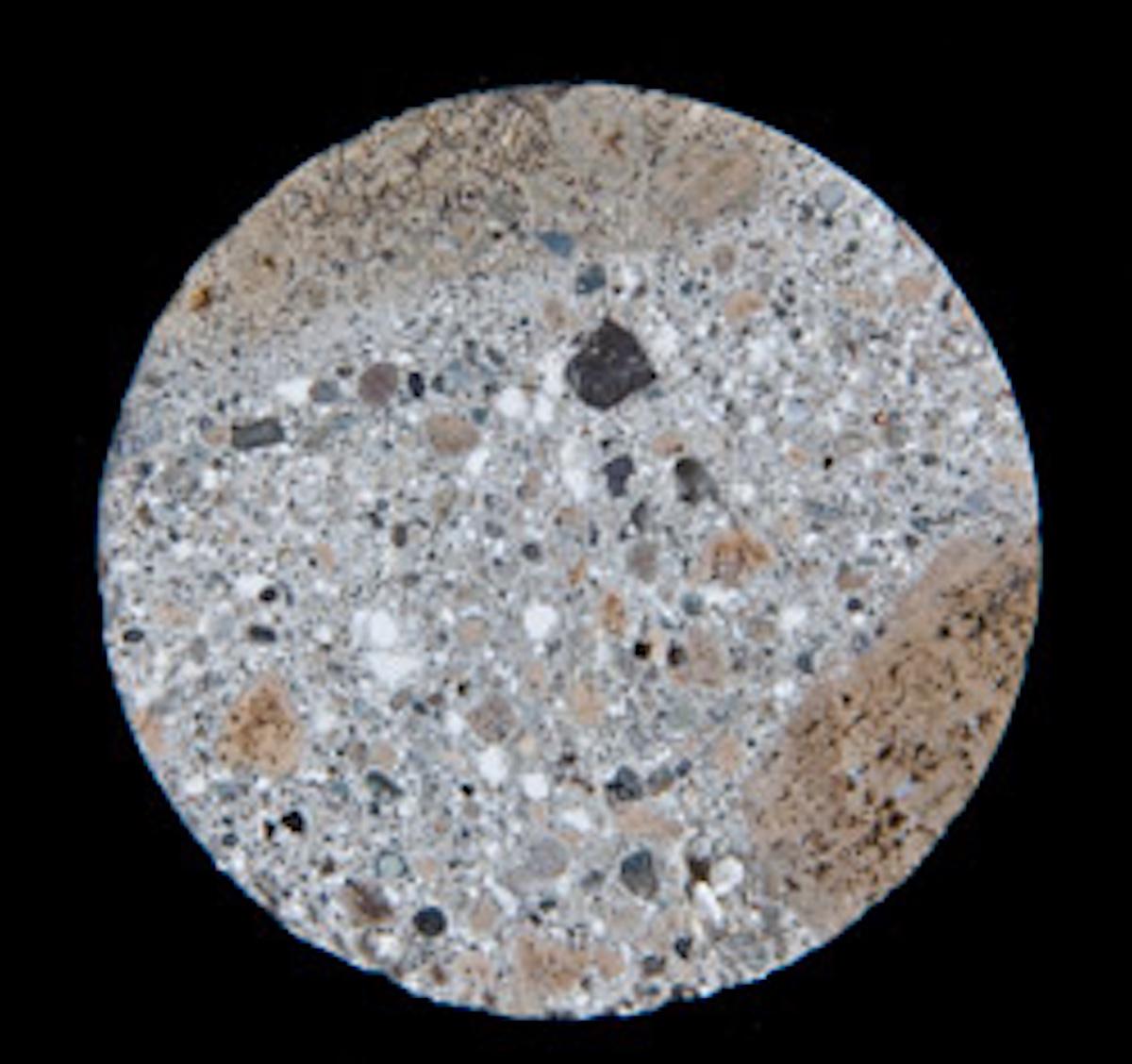

Earlier work by scholars and engineers thought that the unique coffering within the dome’s interior, the thinning of the dome thickness leading up to the oculus, as well as the stress-relieving arches built into the walls of the rotunda were the reasons behind this engineering marvel. Later, more sophisticated analyses of the concrete used to construct the dome found that broken bits of pottery were added to the concrete mixture to help lighten the load of the material while stretching its use.